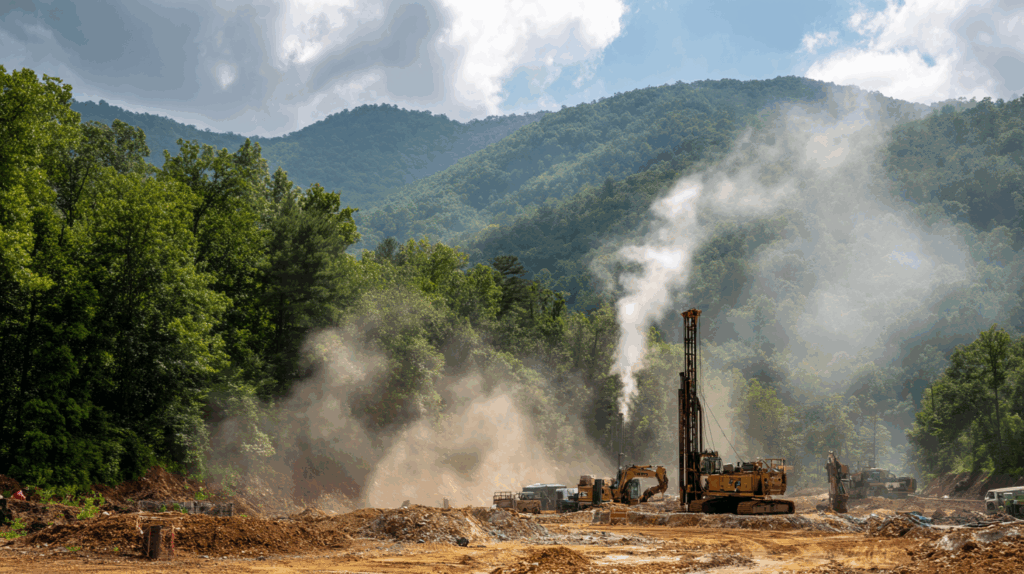

Rock removal done right—for our terrain and your timeline.

Davis & Sons delivers rock drilling and controlled blasting for site pads, utility trenches, and roadway cuts. We plan the work, notify stakeholders, protect surroundings with mats and scaled charges, and document every shot with seismographs and blaster’s reports, so you can advance earthwork without surprises.

What we do

- Production & trench blasting for mass rock, foundations, and utilities.

- Presplit/line drilling to control overbreak and protect faces.

- Seismograph monitoring (ground vibration/airblast) with field-ready reporting.

- Flyrock control with mats, stemming, and timing; clean muck-out and haul-off.

- Documentation: blaster’s records, shot logs, and seismograph files for closeout.

How we work (the Davis & Sons way)

- Pre-blast planning – geotech review, utilities, access, and blast plan. Where blasting is used, we coordinate 72-hour notice to the Tennessee Department of Commerce & Insurance and provide pre-blast survey offers to nearby owners, per state law.

- Drill & load – correct burden/spacings, decking, and delays; mats where required. Qualified, authorized personnel handle explosive loading and initiation.

- Fire & monitor – seismographs placed to record PPV and airblast; results checked against limits and shared with the team.

- Scale, muck, and dress – safe scaling, clean mucking, and turn-over for grading, utilities, or paving.

Safety & compliance

- OSHA 29 CFR 1926 Subpart U governs blasting in construction: only authorized, qualified persons handle explosives; standards cover storage, loading, transportation, and firing.

- ATF 27 CFR Part 555 regulates explosives commerce and storage; materials are kept in locked magazines that meet Subpart K standards.

- Tennessee requirements: blasters/handlers/firms are licensed by the State Fire Marshal; blasts are noticed to the state 72 hours in advance; state allowable levels are 2.0 in/s PPV and 140 dB airblast.

- Pre-blast surveys: Offered to eligible neighbors; when requested, surveys are completed before blasting and documentation provided.

- Vibration good practice: We follow ISEE guidance for seismograph performance and placement; FHWA resources inform communication and management near sensitive receptors.

Typical projects

- Building pads and industrial sites in rock

- Utility trench cuts through limestone/shale

- Roadway cuts, widenings, and slope reductions

- Controlled trench shots in congested corridors

Why Davis & Sons

- Mountain-tested execution on steep grades and tight access.

- Integrated earthwork—we drill/blast, then grade, haul, and build utilities.

- Transparent records—state notices, blaster’s reports, and seismograph files ready for your project folder.

Service area

Tri-Cities & the I-81/I-26 corridor: Kingsport, Johnson City, Bristol, and surrounding Northeast Tennessee counties—plus nearby Southwest Virginia.

FAQs

Will you handle state notices and pre-blast surveys?

Yes. We coordinate the 72-hour state notice and offer pre-blast surveys where required; requested surveys are completed prior to blasting and documented.

What vibration limits do you use?

We monitor every shot and compare to Tennessee’s allowable 2.0 in/s PPV and 140 dB airblast; records are archived with your job files.

Who manages explosive storage and handling?

Licensed blasters handle storage/transport per ATF 27 CFR Part 555 and OSHA construction standards; magazines conform to Subpart K.

Do you use seismographs at structures?

Yes—placement and calibration follow ISEE field practice guidelines to ensure reliable PPV/airblast data.

Need rock moved on a tight window?

- Request a blasting plan (patterns, mats, monitoring, notifications).

- Schedule a site walk to confirm access, safety zones, and sequencing with utilities and grading.

- Ask dispatch about pairing hauling + grading to keep production moving after each shot.